Case Study: United Technologies Corporation

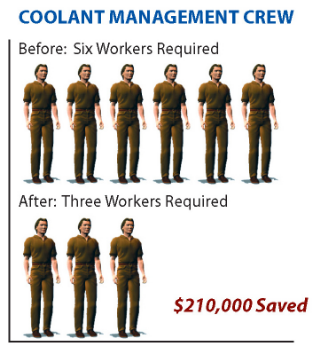

$2.65 Million Saved with Master Fluid and a Coolant Management Program

Hamilton-Sunstrand, a division of United Technologies Corporation, established a coolant committee with representatives for the plant management, health an safety, manufacturing, engineering, purchasing, maintenance, and machine operators. The program included:

Training sessions

Implementation of ongoing recycling systems

Monitoring of coolant and machine sump conditions

These results were obtained:

This is how you can gain from our experience no matter your company size. Quality coolants, cleaners, and recycling equipment are an investment in your company’s future prosperity.

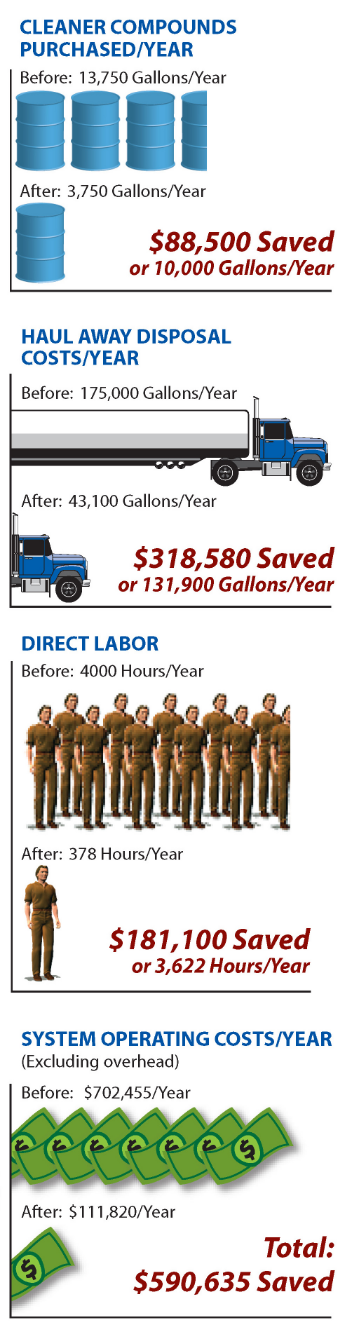

Case Study: Reduction in Use & Disposals of Cleaner Chemistry

Out Cleaning The Competition - Saving through Correct Cleaner Selection

Problem:

A major rebuilder of automotive axles had high operation costs and capacity constraints.

Frequent and expensive dumping of system

Productivity losses due to machine downtime

Increasing energy costs

High labor costs to dump, clean and recharge system

Solution:

Coolant Management worked with the customer’s management and operations staff to produce a solution that integrated the best available technology — both chemical and equipment.

Cleaning chemistry that would efficiently remove difficult greases

Equipment that could quickly separate the heavy soil load from the cleaner bath

Process development to optimize system up-time and minimize disposal

On-going support as customer’s production increased and new and improved processes and equipment were added

Result:

This partnership delivered immediate operating and financial impact.

Capacityincreased by 32.4%

Expenses reduced by 84.1%

$590,635 operating income improvement